Daim ntawv thov ntawmLub ntiaj teb tsis tshua muajhauv Composite Materials

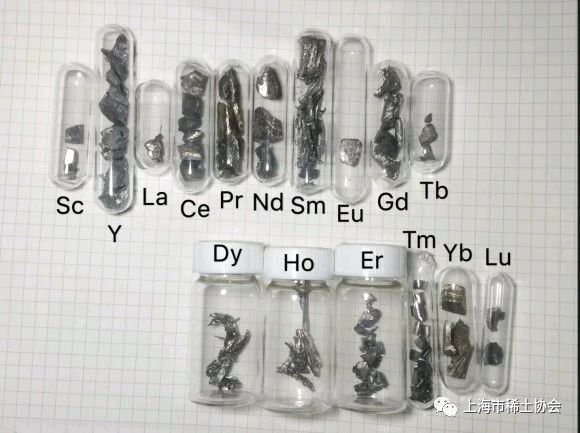

Cov ntsiab lus tsis tshua muaj hauv ntiaj teb muaj 4f cov qauv hluav taws xob tshwj xeeb, lub sijhawm loj atomic sib nqus, muaj zog spin coupling thiab lwm yam ntxwv. Thaum tsim cov complexes nrog lwm cov ntsiab lus, lawv tus lej sib koom ua ke tuaj yeem sib txawv ntawm 6 mus rau 12. Cov tebchaw tsis tshua muaj hauv ntiaj teb muaj ntau yam qauv siv lead ua. Cov khoom tshwj xeeb ntawm lub cev thiab tshuaj lom neeg ntawm lub ntiaj teb tsis tshua muaj ua rau lawv tau siv dav hauv kev sib xyaw ntawm cov hlau zoo thiab cov hlau tsis muaj hlau, cov iav tshwj xeeb thiab cov khoom siv ua haujlwm siab, cov khoom siv hlau nplaum ruaj khov, cov khoom siv hydrogen, cov ntaub ntawv luminescent thiab laser, cov ntaub ntawv nuclear, thiab lwm yam. Nrog rau kev txhim kho txuas ntxiv ntawm cov ntaub ntawv sib xyaw, daim ntawv thov ntawm lub ntiaj teb tsis tshua muaj kuj tau nthuav dav mus rau thaj chaw ntawm cov ntaub ntawv sib xyaw, nyiam cov neeg siv khoom thoob plaws hauv kev txhim kho cov khoom sib txuas ntawm cov ntaub ntawv heterogeneous.

Cov ntawv thov tseem ceeb ntawm lub ntiaj teb tsis tshua muaj nyob rau hauv kev npaj cov ntaub ntawv sib xyaw suav nrog: ① ntxivtsawg ntiaj teb hlaurau cov khoom sib xyaw; ② Ntxiv rau hauv daim ntawv ntawmtsawg ntiaj teb oxidesrau cov khoom sib xyaw; ③ Polymers doped los yog bonded nrog tsawg lub ntiaj teb hlau nyob rau hauv polymers yog siv los ua matrix cov ntaub ntawv nyob rau hauv cov ntaub ntawv sib xyaw. Ntawm cov saum toj no peb daim ntawv thov ntawm lub ntiaj teb tsis tshua muaj, thawj ob daim ntawv feem ntau yog ntxiv rau hlau matrix composite, thaum lub thib peb yog tsuas yog siv rau polymer matrix composites, thiab ceramic matrix composite yog tsuas yog ntxiv rau hauv daim ntawv thib ob.

Tsis tshua muaj ntiaj tebFeem ntau ua rau cov hlau matrix thiab ceramic matrix composite nyob rau hauv daim ntawv ntawm additives, stabilizers, thiab sintering additives, zoo heev txhim kho lawv cov kev ua tau zoo, txo nqi ntau lawm, thiab ua rau nws muaj peev xwm siv tau.

Qhov sib ntxiv ntawm cov ntsiab lus tsis tshua muaj hauv ntiaj teb raws li cov khoom ntxiv hauv cov ntaub ntawv sib xyaw feem ntau ua lub luag haujlwm hauv kev txhim kho kev sib txuas ntawm cov ntaub ntawv sib xyaw thiab txhawb kev ua kom zoo ntawm cov hlau matrix nplej. Lub mechanism ntawm kev txiav txim yog raws li nram no.

① Txhim kho lub wettability ntawm cov hlau matrix thiab cov theem reinforcing. Lub electronegativity ntawm lub ntiaj teb tsis tshua muaj cov ntsiab lus tseem tsawg (qhov me me ntawm electronegativity ntawm cov hlau, qhov ntau dua cov electronegativity ntawm nonmetals). Piv txwv li, La yog 1.1, Ce yog 1.12, thiab Y yog 1.22. Lub electronegativity ntawm ntau lub hauv paus hlau Fe yog 1.83, Ni yog 1.91, thiab Al yog 1.61. Yog li ntawd, lub ntiaj teb tsis tshua muaj cov ntsiab lus yuav nyiam adsorb rau ntawm cov qoob loo ntawm cov hlau matrix thiab cov txheej txheem ntxiv thaum lub sij hawm smelting txheej txheem, txo lawv lub zog interface, ua rau cov adhesion ua hauj lwm ntawm lub interface, txo lub wetting lub kaum sab xis, thiab yog li txhim kho lub wettability ntawm lub matrix thiab reinforcement theem. Kev tshawb fawb tau pom tias qhov sib ntxiv ntawm La element rau aluminium matrix zoo txhim kho cov wettability ntawm AlO thiab txhuas kua, thiab txhim kho microstructure ntawm cov khoom sib xyaw.

② Txhawb kev ua kom zoo ntawm cov hlau matrix nplej. Lub solubility ntawm lub ntiaj teb tsis tshua muaj nyob rau hauv cov hlau siv lead ua yog me me, vim hais tias lub atomic vojvoog ntawm lub ntiaj teb tsis tshua muaj cov ntsiab lus yog loj, thiab atomic vojvoog ntawm hlau matrix kuj me me. Kev nkag mus ntawm cov ntsiab lus tsis tshua muaj hauv ntiaj teb nrog lub vojvoog loj dua rau hauv matrix lattice yuav ua rau lattice distortion, uas yuav ua rau kom lub zog muaj zog. Txhawm rau tswj hwm lub zog qis tshaj plaws, tsis tshua muaj lub ntiaj teb atoms tuaj yeem txhawb nqa ntawm cov kab lis kev cai tsis tu ncua, uas rau qee qhov cuam tshuam kev loj hlob dawb ntawm matrix nplej. Nyob rau tib lub sijhawm, cov ntsiab lus tsis tshua muaj hauv ntiaj teb tseem yuav adsorb lwm cov ntsiab lus alloy, ua kom cov concentration gradient ntawm cov ntsiab lus alloy, ua rau cov khoom hauv zos undercooling, thiab txhim kho cov txiaj ntsig heterogeneous nucleation ntawm cov kua hlau matrix. Tsis tas li ntawd, lub undercooling tshwm sim los ntawm elemental segregation kuj txhawb kev tsim cov segregated compounds thiab ua tau zoo heterogeneous nucleation hais, yog li txhawb cov refinement ntawm cov hlau matrix nplej.

③ Purify cov ciam teb. Vim muaj kev sib raug zoo ntawm lub ntiaj teb tsis tshua muaj cov ntsiab lus thiab cov ntsiab lus xws li O, S, P, N, thiab lwm yam, tus qauv pub dawb ntawm kev tsim rau oxides, sulfides, phosphides, thiab nitrides tsawg. Cov tebchaw tau muaj lub siab zoo me me thiab qis dua, qee tus tuaj yeem muab tshem tawm ntawm cov qoob loo ntawm cov noob qoob loo ntawm cov nplej zom, yog li muaj cov qoob loo ntawm cov nplej thiab txhim kho nws lub zog.

Nws yuav tsum tau muab sau tseg tias, vim muaj kev ua haujlwm siab thiab qis melting point ntawm cov hlau tsis tshua muaj hauv ntiaj teb, thaum lawv ntxiv rau cov hlau matrix composite, lawv cov kev sib cuag nrog oxygen yuav tsum tau tswj tshwj xeeb thaum lub sij hawm ntxiv txheej txheem.

Ntau qhov kev coj ua tau ua pov thawj tias ntxiv cov av tsis tshua muaj oxides li stabilizers, sintering aids, thiab doping modifiers rau txawv hlau matrix thiab ceramic matrix composite tuaj yeem txhim kho lub zog thiab tawv ntawm cov ntaub ntawv, txo lawv cov sintering kub, thiab yog li txo cov nqi tsim khoom. Lub ntsiab mechanism ntawm nws qhov kev txiav txim yog raws li nram no.

① Raws li sintering additive, nws tuaj yeem txhawb sintering thiab txo cov porosity hauv cov khoom sib xyaw. Qhov sib ntxiv ntawm sintering additives yog tsim kom muaj cov kua theem ntawm qhov kub thiab txias, txo qhov kub ntawm sintering ntawm cov ntaub ntawv sib xyaw, inhibit qhov kub-kub decomposition ntawm cov ntaub ntawv thaum lub sij hawm sintering txheej txheem, thiab muab cov ntaub ntawv ntom ntom los ntawm cov kua theem sintering. Vim lub siab ruaj khov, tsis muaj zog-kub volatility, thiab siab melting thiab boiling ntsiab lus ntawm tsawg ntiaj teb oxides, lawv muaj peev xwm tsim iav theem nrog rau lwm yam raw khoom thiab txhawb sintering, ua rau lawv ib tug zoo additive. Nyob rau tib lub sijhawm, lub ntiaj teb tsis tshua muaj oxide kuj tuaj yeem tsim cov khoom siv nrog cov ceramic matrix, uas tuaj yeem tsim cov khoom siv lead ua tsis xws hauv, qhib lub lattice thiab txhawb sintering.

② Txhim kho microstructure thiab refine grain loj. Vim lub fact tias lub ntiaj teb tsis tshua muaj ntxiv oxides feem ntau muaj nyob rau ntawm lub grain ciam teb ntawm lub matrix, thiab vim lawv loj ntim, tsis tshua muaj ntiaj teb oxides muaj siab tsiv teb tsaws nyob rau hauv cov qauv, thiab tseem cuam tshuam kev tsiv teb tsaws ntawm lwm yam ions, yog li txo qhov kev tsiv teb tsaws ntawm grain ciam teb, inhibiting grain kev loj hlob, thiab cuam tshuam qhov txawv txav ntawm cov nplej thaum lub sij hawm high-temperature. Lawv tuaj yeem tau txais cov nplej me me thiab zoo ib yam, uas yog qhov tsim nyog rau kev tsim cov qauv ntom ntom; Ntawm qhov tod tes, los ntawm doping tsis tshua muaj lub ntiaj teb oxides, lawv nkag mus rau lub grain ciam iav theem, kev txhim kho lub zog ntawm lub iav theem thiab yog li ua tiav lub hom phiaj ntawm kev txhim kho cov neeg kho tshuab zog ntawm cov khoom.

Tsis tshua muaj lub ntiaj teb cov ntsiab lus hauv polymer matrix composites feem ntau cuam tshuam rau lawv los ntawm kev txhim kho cov khoom ntawm polymer matrix. Tsis tshua muaj lub ntiaj teb oxides tuaj yeem ua rau cov thermal decomposition kub ntawm polymers, thaum lub ntiaj teb tsis tshua muaj carboxylates tuaj yeem txhim kho thermal stability ntawm polyvinyl chloride. Doping polystyrene nrog lub ntiaj teb tsis tshua muaj sib txuas tuaj yeem txhim kho kev ruaj ntseg ntawm polystyrene thiab ua kom nws lub zog cuam tshuam thiab khoov lub zog.

Post lub sij hawm: Apr-26-2023