Ntawm cov non-siliceous oxides, alumina muaj cov khoom zoo, kub tsis kam thiab corrosion kuj, thaum mesoporous alumina (MA) muaj adjustable pore loj, loj tshwj xeeb deg cheeb tsam, loj pore ntim thiab tsawg zus tau tej cov nqi, uas yog dav siv nyob rau hauv catalysis, tswj cov tshuaj tso tawm, adsorption thiab lwm yam teb, xws li tawg, hydrocracking thiab peculiar luminous cov ntaub ntawv. siv hauv kev lag luam, tab sis nws yuav cuam tshuam ncaj qha rau kev ua haujlwm ntawm alumina, kev pabcuam lub neej thiab kev xaiv ntawm catalyst. Piv txwv li, nyob rau hauv tus txheej txheem ntawm lub tsheb tso pa purification, cov deposits pollutants los ntawm engine roj additives yuav tsim coke, uas yuav ua rau lub blockage ntawm catalyst pores, yog li txo cov kev ua ntawm catalyst. Surfactant tuaj yeem siv los kho cov qauv ntawm alumina carrier los ua MA.Txhim kho nws cov catalytic kev ua tau zoo.

MA muaj kev txwv tsis pub siv, thiab cov hlau nquag ua haujlwm tsis zoo tom qab kub kub calcination. Tsis tas li ntawd, tom qab kub kub calcination, cov qauv mesoporous tawg, lub cev pob txha MA yog nyob rau hauv lub xeev amorphous, thiab cov acidity saum npoo tsis tuaj yeem ua tau raws li nws cov kev xav tau hauv kev ua haujlwm. Kev hloov kho kev kho mob feem ntau xav tau los txhim kho cov kev ua haujlwm catalytic, cov qauv mesoporous stability, nto thermal stability thiab nto acidity ntawm MA cov ntaub ntawv.Cov kev hloov kho pab pawg muaj xws li hlau heteroatoms (Fe, Co, Ni, Cu, Zn, Pd, Pt, Zr, thiab lwm yam) thiab hlau oxides (TiO2, NiO, Co3O4, CuO2OMA2O, thiab lwm yam.) thiab lwm yam. rau hauv lub cev.

Qhov tshwj xeeb electron configuration ntawm tsawg lub ntiaj teb cov ntsiab lus ua rau nws cov tebchaw muaj tshwj xeeb kho qhov muag, hluav taws xob thiab sib nqus zog, thiab yog siv nyob rau hauv catalytic cov ntaub ntawv, photoelectric cov ntaub ntawv, cov khoom adsorption thiab magnetic ntaub ntawv. Tsis tshua muaj lub ntiaj teb hloov cov ntaub ntawv mesoporous tuaj yeem kho cov kua qaub (alkali) cov cuab yeej, ua kom cov pa tsis txaus, thiab ua kom cov hlau nanocrystalline catalyst nrog cov dispersion zoo thiab ruaj khov nanometer scale.Appropriate porous cov ntaub ntawv thiab tsis tshua muaj lub ntiaj teb tuaj yeem txhim kho qhov chaw dispersion ntawm hlau nanocrystals thiab stability thiab carbon deposition tsis kam ntawm catalysts. Hauv daim ntawv no, tsis tshua muaj kev hloov kho hauv ntiaj teb thiab kev ua haujlwm ntawm MA yuav raug qhia los txhim kho catalytic kev ua tau zoo, thermal stability, oxygen cia peev xwm, tshwj xeeb thaj chaw thiab pore qauv.

1 MA kev npaj

1.1 kev npaj ntawm alumina cab kuj

Txoj kev npaj ntawm alumina carrier txiav txim siab nws qhov pore qauv faib, thiab nws txoj kev npaj muaj xws li pseudo-boehmite (PB) dehydration method thiab sol-gel method. Pseudoboehmite (PB) yog thawj zaug los ntawm Calvet, thiab H + txhawb peptization kom tau γ-AlOOH colloidal PB uas muaj dej interlayer, uas yog calcined thiab lub cev qhuav dej ntawm qhov kub thiab txias los tsim alumina. Raws li cov ntaub ntawv sib txawv, nws feem ntau muab faib rau hauv txoj kev nag lossis daus, carbonization txoj kev thiab cawv aluminum hydrolysis method.Cov colloidal solubility ntawm PB cuam tshuam los ntawm crystallinity, thiab nws yog optimized nrog nce crystallinity, thiab tseem cuam tshuam los ntawm kev khiav hauj lwm cov txheej txheem tsis.

PB feem ntau yog npaj los ntawm txoj kev los nag. Alkali yog ntxiv rau hauv aluminate tov los yog acid ntxiv rau hauv aluminate tov thiab precipitated kom tau hydrated alumina (alkali nag lossis daus), los yog acid ntxiv rau hauv aluminate nag lossis daus kom tau alumina monohydrate, uas tom qab ntawd ntxuav, qhuav thiab calcined kom tau PB. Txoj kev nag lossis daus yog ib qho yooj yim rau kev khiav lag luam thiab tus nqi qis, uas feem ntau yog siv hauv kev tsim khoom, tab sis nws cuam tshuam los ntawm ntau yam (kev daws teeb meem pH, concentration, kub, thiab lwm yam). Hauv txoj kev carbonization, Al (OH) 3 yog tau los ntawm cov tshuaj tiv thaiv ntawm CO2 thiab NaAlO2, thiab PB tuaj yeem tau txais tom qab kev laus. Txoj kev no muaj qhov zoo ntawm kev ua haujlwm yooj yim, cov khoom lag luam zoo, tsis muaj kuab paug thiab tus nqi qis, thiab tuaj yeem npaj alumina nrog kev ua haujlwm siab catalytic, zoo heev corrosion kuj thiab siab tshwj xeeb deg cheeb tsam nrog tsawg peev thiab siab rov qab.Aluminium alkoxide hydrolysis txoj kev yog feem ntau siv los npaj high-purity PB. Aluminium alkoxide yog hydrolyzed los tsim aluminium oxide monohydrate, thiab tom qab ntawd kho kom tau txais high-purity PB, uas muaj cov crystallinity zoo, cov khoom me me, cov ntsiab lus ntawm qhov pore loj thiab muaj kev ntseeg siab ntawm cov khoom kheej kheej. Txawm li cas los xij, cov txheej txheem yog qhov nyuaj, thiab nws nyuaj rau rov qab los vim yog siv qee yam tshuaj lom cov kuab tshuaj lom.

Tsis tas li ntawd, cov ntsev inorganic los yog cov organic sib txuas ntawm cov hlau feem ntau yog siv rau kev npaj alumina precursors los ntawm sol-gel txoj kev, thiab cov dej ntshiab los yog cov kuab tshuaj organic ntxiv los npaj cov kev daws teeb meem los tsim cov sol, uas yog tom qab ntawd gelled, qhuav thiab ci. Tam sim no, cov txheej txheem kev npaj ntawm alumina tseem txhim kho raws li PB lub cev qhuav dej, thiab cov txheej txheem carbonization tau dhau los ua txoj hauv kev tseem ceeb rau kev lag luam alumina vim nws kev lag luam thiab kev tiv thaiv ib puag ncig.

1.2 MA kev npaj

Pa alumina tsis tuaj yeem ua tau raws li qhov yuav tsum tau ua, yog li nws yog qhov tsim nyog los npaj MA ua haujlwm siab. Cov txheej txheem synthesis feem ntau muaj xws li: nano-casting txoj kev nrog carbon pwm ua nyuaj template; Synthesis of SDA: Evaporation-induced self-assembly process (EISA) nyob rau hauv lub xub ntiag ntawm mos templates xws li SDA thiab lwm yam cationic, anionic los yog nonionic surfactants.

1.2.1 EISA process

Cov qauv muag muag yog siv rau hauv acidic mob, uas zam cov txheej txheem nyuaj thiab siv sij hawm ntawm cov txheej txheem tawv tawv thiab tuaj yeem paub qhov kev hloov pauv tas li ntawm aperture. Kev npaj ntawm MA los ntawm EISA tau nyiam ntau yam vim nws yooj yim muaj thiab rov tsim dua tshiab. Cov qauv mesoporous sib txawv tuaj yeem npaj tau. Lub pore loj ntawm MA tuaj yeem hloov kho los ntawm kev hloov cov saw hydrophobic ntev ntawm surfactant los yog kho cov molar ratio ntawm hydrolysis catalyst rau txhuas precursor hauv kev daws teeb meem.Yog li ntawd, EISA, kuj hu ua ib-kauj ruam synthesis thiab hloov kho sol-gel txoj kev ntawm qhov chaw siab MA thiab txiav txim mesoporous alumina (OMA), tau siv rau ntau yam, xws li cov khoom siv 1-2, 1. (tshuaj yej), thiab lwm yam. EISA tuaj yeem hloov cov txheej txheem co-assembly ntawm organoaluminum precursors, xws li aluminium alkoxides thiab surfactant templates, feem ntau yog aluminium isopropoxide thiab P123, rau kev muab cov ntaub ntawv mesoporous.Qhov kev vam meej ntawm EISA txheej txheem yuav tsum muaj kev hloov kho ntawm hydrolysis thiab condensation kinsols ntawm surfactase kev txhim kho kom ruaj khov. micelles hauv sol.

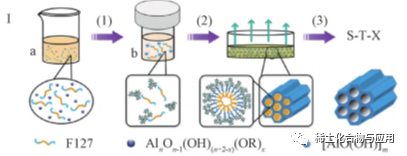

Hauv cov txheej txheem EISA, kev siv cov kuab tshuaj tsis muaj dej (xws li ethanol) thiab cov organic complexing agents tuaj yeem ua kom cov hydrolysis thiab condensation tus nqi ntawm organoaluminum precursors thiab induce tus kheej-assembly ntawm OMA cov ntaub ntawv, xws li Al (OR) 3 thiab txhuas isopropoxide. Txawm li cas los xij, hauv cov kuab tshuaj tsis muaj dej tsis haum, cov qauv surfactant feem ntau poob lawv cov hydrophilicity / hydrophobicity. Tsis tas li ntawd, Vim muaj kev ncua ntawm hydrolysis thiab polycondensation, cov khoom nruab nrab muaj hydrophobic pawg, uas ua rau nws nyuaj rau kev cuam tshuam nrog surfactant template. Tsuas yog thaum cov concentration ntawm surfactant thiab qib ntawm hydrolysis thiab polycondensation ntawm txhuas yog maj mam nce nyob rau hauv tus txheej txheem ntawm hnyav evaporation yuav tus kheej-assembly ntawm template thiab txhuas coj qhov chaw. Yog li ntawd, ntau yam tsis zoo uas cuam tshuam rau evaporation tej yam kev mob ntawm cov kuab tshuaj thiab cov hydrolysis thiab condensation cov tshuaj tiv thaiv ntawm precursors, xws li kub, txheeb ze humidity, catalyst, hnyav evaporation tus nqi, thiab lwm yam., yuav cuam tshuam rau lub kawg sib dhos qauv. Raws li qhia hauv daim duab. 1, OMA cov ntaub ntawv uas muaj thermal stability thiab siab catalytic kev ua tau zoo yog synthesized los ntawm solvothermal assisted evaporation induced self-assembly (SA-EISA). solvothermal kev kho mob txhawb kev ua tiav hydrolysis ntawm aluminium precursors los tsim cov pawg me me ntawm txhuas hydroxyl pawg, uas txhim kho kev sib cuam tshuam ntawm surfactants thiab txhuas. Hauv cov txheej txheem EISA ib txwm muaj, cov txheej txheem evaporation yog nrog los ntawm hydrolysis ntawm organoaluminum precursor, yog li cov txheej txheem evaporation muaj qhov cuam tshuam tseem ceeb ntawm cov tshuaj tiv thaiv thiab cov qauv kawg ntawm OMA. Cov kauj ruam kho solvothermal txhawb kev ua tiav hydrolysis ntawm aluminium precursor thiab tsim ib nrab condensed clustered aluminium hydroxyl pawg.OMA yog tsim nyob rau hauv ntau yam ntawm evaporation tej yam kev mob. Piv nrog MA npaj los ntawm cov txheej txheem EISA ib txwm, OMA npaj los ntawm SA-EISA txoj kev muaj ntau dua qhov pore ntim, zoo dua qhov chaw nto thiab zoo thermal stability. Nyob rau hauv lub neej yav tom ntej, EISA txoj kev yuav siv tau los npaj ultra-loj aperture MA nrog kev hloov siab los ntseeg siab thiab kev xaiv zoo heev yam tsis siv tus neeg sawv cev reaming.

Fig. 1 flow chart of SA-EISA method for synthesizing OMA cov ntaub ntawv

1.2.2 lwm cov txheej txheem

Pa MA kev npaj yuav tsum muaj kev tswj xyuas cov kev sib txuas ua ke kom ua tiav cov qauv meej mesoporous, thiab kev tshem tawm cov ntaub ntawv template kuj nyuaj, uas ua rau cov txheej txheem synthesis nyuaj. Tam sim no, ntau cov ntaub ntawv tau tshaj tawm txog kev sib txuas ntawm MA nrog cov qauv sib txawv. Nyob rau hauv xyoo tas los no, kev tshawb fawb feem ntau tsom rau kev sib txuas ntawm MA nrog cov piam thaj, sucrose thiab cov hmoov txhuv nplej siab raws li cov qauv ntawm aluminium isopropoxide hauv cov kua dej aqueous.Feem ntau ntawm cov ntaub ntawv MA no yog tsim los ntawm txhuas nitrate, sulfate thiab alkoxide ua txhuas qhov chaw. MA CTAB kuj tau txais los ntawm kev hloov pauv ncaj qha ntawm PB li txhuas qhov chaw. MA nrog cov khoom sib txawv, piv txwv li Al2O3)-1, Al2O3)-2 thiab al2o3Thiab muaj thermal stability zoo. Qhov sib ntxiv ntawm surfactant tsis hloov cov qauv siv lead ua ntawm PB, tab sis hloov cov txheej txheem ntawm cov khoom. Tsis tas li ntawd, qhov tsim ntawm Al2O3-3 yog tsim los ntawm adhesion ntawm nanoparticles stabilized los ntawm organic hnyav PEG los yog aggregation nyob ib ncig ntawm PEG. Txawm li cas los xij, qhov pore loj faib ntawm Al2O3-1 yog nqaim heev. Tsis tas li ntawd, palladium-based catalysts tau npaj nrog hluavtaws MA raws li cov cab kuj.In methane combustion cov tshuaj tiv thaiv, cov catalyst txhawb nqa los ntawm Al2O3-3 pom zoo catalytic kev ua tau zoo.

Thawj thawj zaug, MA nrog qhov nqaim qhov pore loj faib tau npaj los ntawm kev siv pheej yig thiab nplua nuj txhuas txhuas dub slag ABD. Cov txheej txheem ntau lawm suav nrog cov txheej txheem rho tawm ntawm qhov kub thiab txias ib txwm muaj. Cov khoom seem uas tshuav nyob rau hauv cov txheej txheem rho tawm yuav tsis ua qias neeg ib puag ncig, thiab tuaj yeem piled nrog tsis tshua muaj kev pheej hmoo lossis rov siv dua los ua muab tub lim lossis sib sau ua ke hauv daim ntawv thov pob zeb. Qhov chaw tshwj xeeb ntawm cov khoom sib txuas MA yog 123 ~ 162m2 / g, qhov pore loj faib yog nqaim, lub ncov lub vojvoog yog 5.3nm, thiab qhov porosity yog 0.37 cm3 / g. Cov khoom siv yog nano-loj thiab siv lead ua loj yog li 11nm. Solid-state synthesis yog txheej txheem tshiab los ua ke MA, uas tuaj yeem siv los tsim cov tshuaj radiochemical absorbent rau kev kho mob. Aluminium chloride, ammonium carbonate thiab qabzib raw cov ntaub ntawv yog tov nyob rau hauv ib tug molar piv ntawm 1: 1.5: 1.5, thiab MA yog synthesized los ntawm ib tug tshiab solid-state mechanochemical cov tshuaj tiv thaiv.By concentrating131I nyob rau hauv thermal roj teeb khoom, tag nrho cov yield ntawm 131I tom qab concentration yog 90%, thiab cov tau txais ib tug high concentration 131I. (1.7TBq/mL), yog li paub txog kev siv cov koob tshuaj loj 131I [NaI] capsules rau kev kho mob qog noj ntshav.

Txhawm rau ua kom tiav, yav tom ntej, cov qauv me me me tuaj yeem tsim kho los tsim cov txheej txheem ntau theem ntawm qhov pore, kho cov qauv zoo, morphology thiab cov khoom siv tshuaj lom neeg ntawm cov khoom, thiab tsim cov cheeb tsam loj thiab xaj wormhole MA. Tshawb nrhiav cov qauv pheej yig thiab cov khoom siv txhuas, txhim kho cov txheej txheem synthesis, qhia meej cov txheej txheem synthesis thiab coj cov txheej txheem.

Txoj kev hloov kho ntawm 2 MA

Cov txheej txheem ntawm kev faib cov khoom siv sib xyaw ua ke ntawm MA cov cab kuj suav nrog impregnation, in-situ synthe-sis, nag lossis daus, ion txauv, kev sib xyaw ua ke thiab melting, uas yog thawj ob feem ntau siv.

2.1 nyob rau hauv-situ synthesis method

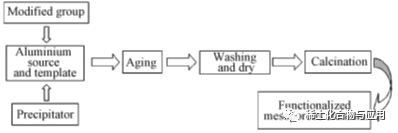

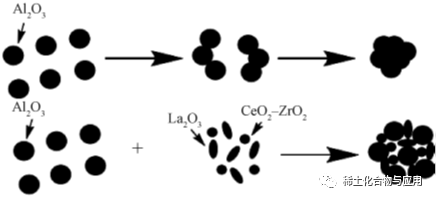

Cov pab pawg siv hauv kev hloov kho kev ua haujlwm tau ntxiv rau hauv cov txheej txheem ntawm kev npaj MA los hloov kho thiab txhim kho lub cev pob txha ntawm cov khoom siv thiab txhim kho kev ua haujlwm catalytic. Cov txheej txheem muaj nyob rau hauv daim duab 2. Liu et al. synthesized Ni/Mo-Al2O3in situ nrog P123 raws li template. Ob Ni thiab Mo tau tawg mus rau hauv kev txiav txim MA raws, yam tsis tau rhuav tshem cov qauv mesoporous ntawm MA, thiab kev ua haujlwm catalytic tau pom tseeb zoo dua. Kev siv txoj hauv kev loj hlob hauv qhov chaw ntawm cov khoom sib txuas gamma-al2o3substrate, Piv nrog γ-Al2O3, MnO2-Al2O3 muaj qhov loj dua BET tshwj xeeb thaj chaw thiab qhov pore ntim, thiab muaj cov qauv bimodal mesoporous nrog nqaim pore loj faib. MnO2-Al2O3 muaj tus nqi nrawm nrawm thiab ua haujlwm siab rau F-, thiab muaj qhov dav pH daim ntawv thov ntau yam (pH = 4 ~ 10), uas yog tsim rau cov kev siv hauv kev lag luam. Kev ua haujlwm rov ua dua tshiab ntawm MnO2-Al2O3 zoo dua li ntawm γ-Al2O.Structural stability yuav tsum tau ua kom zoo ntxiv. Piv txwv li, MA hloov cov ntaub ntawv tau txais los ntawm in-situ synthesis muaj cov qauv zoo, kev sib raug zoo ntawm cov pab pawg thiab cov neeg nqa khoom alumina, kev sib xyaw ua ke, cov khoom siv loj, thiab tsis yooj yim los ua kom cov khoom ua haujlwm hauv cov txheej txheem catalytic, thiab cov catalytic kev ua tau zoo tuaj.

Fig. 2 Kev npaj ntawm functionalized MA los ntawm in-situ synthesis

2.2 txoj kev impregnation

immersing MA npaj rau hauv pab pawg hloov kho, thiab tau txais cov khoom hloov kho MA tom qab kev kho mob, kom paub txog cov teebmeem ntawm catalysis, adsorption thiab lwm yam. Cai et al. npaj MA los ntawm P123 los ntawm sol-gel txoj kev, thiab soaked nyob rau hauv ethanol thiab tetraethylenepentamine tov kom tau cov amino hloov MA cov ntaub ntawv uas muaj zog adsorption kev ua tau zoo. Tsis tas li ntawd, Belkacemi et al. dipped nyob rau hauv ZnCl2solution los ntawm tib cov txheej txheem kom tau txais zinc doped hloov MA cov ntaub ntawv.Qhov tshwj xeeb nto thiab pore ntim yog 394m2 / g thiab 0.55 cm3 / g, feem. Piv nrog rau cov txheej txheem hauv-situ synthesis, txoj kev impregnation muaj cov ntsiab lus zoo dua dispersion, ruaj khov mesoporous qauv thiab zoo adsorption kev ua tau zoo, tab sis kev sib cuam tshuam quab yuam ntawm cov khoom siv thiab cov khoom siv alumina tsis muaj zog, thiab cov kev ua catalytic tau yooj yim cuam tshuam los ntawm lwm yam.

3 kev ua haujlwm tau zoo

Lub synthesis ntawm lub ntiaj teb tsis tshua muaj MA nrog cov khoom tshwj xeeb yog kev txhim kho yav tom ntej. Tam sim no, muaj ntau txoj kev sib txuas. Cov txheej txheem tsis cuam tshuam rau kev ua haujlwm ntawm MA. Qhov tshwj xeeb ntawm thaj chaw, qhov pore ntim thiab pore txoj kab uas hla ntawm MA tuaj yeem hloov kho los ntawm hom template thiab aluminium precursor muaj pes tsawg leeg. Lub calcination kub thiab polymer template concentration cuam tshuam rau thaj chaw tshwj xeeb thiab pore ntim ntawm MA. Suzuki thiab Yamauchi pom tias qhov kub ntawm calcination tau nce los ntawm 500 ℃ mus rau 900 ℃ .Qhov aperture tuaj yeem nce ntxiv thiab qhov chaw saum npoo tuaj yeem txo qis. Tsis tas li ntawd, lub ntiaj teb tsis tshua muaj kev hloov kho kho txhim kho kev ua haujlwm, qhov chaw thermal stability, cov qauv kev ruaj ntseg thiab cov acidity ntawm MA cov ntaub ntawv hauv cov txheej txheem catalytic, thiab ua tau raws li kev txhim kho ntawm MA functionalization.

3.1 Defluorination Adsorbent

Cov tshuaj fluorine hauv cov dej haus hauv Suav teb yog teeb meem loj. Tsis tas li ntawd, qhov nce ntawm fluorine cov ntsiab lus nyob rau hauv industrial zinc sulfate tov yuav ua rau corrosion ntawm electrode phaj, deterioration ntawm kev ua hauj lwm ib puag ncig, poob ntawm qhov zoo ntawm cov hluav taws xob zinc thiab txo tus nqi ntawm recycled dej nyob rau hauv lub acid ua system thiab electrolysis txheej txheem ntawm fluidized txaj rauv roasting flue gas. Tam sim no, txoj kev adsorption yog qhov txaus nyiam tshaj plaws ntawm cov txheej txheem ntub dej defluorination.Txawm li cas los xij, muaj qee qhov tsis zoo, xws li tsis zoo adsorption muaj peev xwm, nqaim muaj pH ntau, cov pa phem thib ob thiab lwm yam. Activated carbon, amorphous alumina, activated alumina thiab lwm yam adsorbents tau siv rau defluorination ntawm dej, tab sis tus nqi ntawm adsorbents yog siab, thiab lub peev xwm adsorption ntawm F-nyob rau hauv nruab nrab kua los yog siab concentration yog tsawg. Nws raug txwv los ntawm qhov tsis zoo adsorption muaj peev xwm ntawm cov tshuaj fluoride, thiab tsuas yog ntawm pH <6 nws tuaj yeem muaj cov tshuaj fluoride adsorption zoo. Kundu et al. npaj MA nrog qhov siab tshaj plaws fluorine adsorption muaj peev xwm ntawm 62.5 mg / g. Lub peev xwm fluorine adsorption ntawm MA tau cuam tshuam zoo heev los ntawm nws cov yam ntxwv, xws li thaj chaw tshwj xeeb, pawg ua haujlwm saum npoo, qhov pore loj thiab tag nrho cov pore loj.Kev kho cov qauv thiab kev ua haujlwm ntawm MA yog ib qho tseem ceeb los txhim kho nws cov adsorption kev ua tau zoo.

Vim lub zog acid ntawm La thiab lub hauv paus nyuaj ntawm fluorine, muaj kev sib raug zoo ntawm La thiab fluorine ions. Nyob rau hauv xyoo tas los no, qee qhov kev tshawb fawb tau pom tias La li kev hloov kho tuaj yeem txhim kho lub peev xwm adsorption ntawm fluoride. Txawm li cas los xij, vim qhov tsis tshua muaj kev ruaj ntseg ntawm lub ntiaj teb tsis tshua muaj adsorbents, ntau lub ntiaj teb tsis tshua muaj leached rau hauv cov kev daws teeb meem, ua rau cov dej qias neeg thib ob thiab ua rau tib neeg noj qab haus huv. Ntawm qhov tod tes, High concentration ntawm txhuas nyob rau hauv dej ib puag ncig yog ib qho tshuaj lom rau tib neeg noj qab haus huv. Yog li ntawd, nws yog ib qho tsim nyog los npaj ib hom kev sib xyaw adsorbent nrog kev ruaj ntseg zoo thiab tsis muaj leaching lossis tsawg leaching ntawm lwm cov ntsiab lus hauv cov txheej txheem tshem tawm fluorine. MA hloov los ntawm La thiab Ce tau npaj los ntawm txoj kev impregnation (La/MA thiab Ce/MA). Tsis tshua muaj lub ntiaj teb oxides tau ntse loaded ntawm MA nto thawj zaug, uas muaj ntau dua defluorination kev ua tau zoo.Lub ntsiab mechanisms ntawm fluorine tshem tawm yog electrostatic adsorption thiab tshuaj adsorption, electron attraction ntawm nto zoo nqi thiab ligand pauv cov tshuaj tiv thaiv ua ke nrog nto hydroxyl, hydroxyl functional pab pawg neeg ntawm lub adsorbent nto generates hydrogen daim ntawv cog lus ntawm F-, fluorine, La / MA muaj ntau qhov chaw hydroxyl adsorption, thiab lub peev xwm adsorption ntawm F yog nyob rau hauv qhov kev txiav txim ntawm La / MA> Ce / MA> MA. Nrog rau qhov nce ntawm thawj zaug concentration, lub peev xwm adsorption ntawm fluorine nce.Cov nyhuv adsorption yog qhov zoo tshaj plaws thaum pH yog 5 ~ 9, thiab cov txheej txheem adsorption ntawm fluorine accords nrog Langmuir isothermal adsorption qauv. Tsis tas li ntawd, cov impurities ntawm sulfate ions hauv alumina kuj tseem cuam tshuam rau qhov zoo ntawm cov qauv. Txawm hais tias cov kev tshawb fawb ntsig txog ntawm lub ntiaj teb tsis tshua muaj hloov pauv alumina tau ua tiav, feem ntau ntawm cov kev tshawb fawb tsom mus rau cov txheej txheem ntawm adsorbent, uas yog qhov nyuaj rau kev siv industrially.Nyob rau hauv lub neej yav tom ntej, peb tuaj yeem kawm txog kev sib cais ntawm cov tshuaj fluorine complex hauv zinc sulfate tov thiab cov yam ntxwv ntawm kev tsiv teb tsaws ntawm fluorine ions, tau txais txiaj ntsig, nqi qis thiab txuas ntxiv fluorine zinc sulfate adsorption ntawm zinc sulfate adsorption. system, thiab tsim kom muaj cov txheej txheem tswj cov qauv rau kev kho cov tshuaj fluorine siab raws li lub ntiaj teb tsis tshua muaj MA nano adsorbent.

3.2 Catalyst

3.2.1 Qhuav hloov ntawm methane

Tsis tshua muaj lub ntiaj teb tuaj yeem kho cov kua qaub (lub hauv paus) ntawm cov ntaub ntawv ntxeem tau, ua kom cov pa tawm tsis txaus, thiab ua kom cov catalysts nrog kev sib cais, nanometer scale thiab stability. Nws feem ntau yog siv los txhawb cov hlau tsis zoo thiab cov hlau hloov mus rau catalyze methanation ntawm CO2. Tam sim no, tsis tshua muaj lub ntiaj teb hloov cov ntaub ntawv mesoporous tab tom txhim kho rau methane qhuav hloov pauv (MDR), photocatalytic degradation ntawm VOCs thiab tail gas purification.Piv nrog cov hlau zoo (xws li Pd, Ru, Rh, thiab lwm yam) thiab lwm yam kev hloov pauv hlau (xws li Co, Fe, thiab lwm yam), Ni / Al2O3catalyst siv ntau dua rau kev ua haujlwm siab thiab kev ruaj ntseg. methane. Txawm li cas los xij, sintering thiab carbon deposition ntawm Ni nanoparticles nyob rau saum npoo ntawm Ni / Al2O3 ua rau lub deactivation sai ntawm catalyst. Yog li ntawd, nws yog ib qho tsim nyog yuav tsum tau ntxiv accelerant, hloov catalyst cab kuj thiab txhim kho txoj kev npaj los txhim kho catalytic kev ua si, stability thiab scorch kuj. Feem ntau, lub ntiaj teb tsis tshua muaj oxides tuaj yeem siv los ua cov txheej txheem thiab cov khoom siv hluav taws xob hauv cov catalysts heterogeneous, thiab CeO2 txhim kho qhov tawg ntawm Ni thiab hloov cov khoom ntawm cov hlau Ni los ntawm kev sib cuam tshuam hlau muaj zog.

MA yog dav siv los txhim kho cov dispersion ntawm cov hlau, thiab muab kev ceev rau cov hlau nquag tiv thaiv lawv cov agglomeration. La2O3 nrog rau cov pa oxygen siab muaj peev xwm txhim kho cov pa roj carbon monoxide hauv cov txheej txheem hloov dua siab tshiab, thiab La2O3 txhawb nqa kev tawg ntawm Co ntawm mesoporous alumina, uas muaj kev hloov kho siab thiab ua haujlwm zoo. Lub La2O3promoter nce MDR kev ua ntawm Co/MA catalyst, thiab Co3O4and CoAl2O4phases yog tsim nyob rau hauv catalyst nto.Txawm li cas los xij, cov khoom tawg heev La2O3 muaj cov nplej me me ntawm 8nm ~ 10nm. Hauv cov txheej txheem MDR, kev sib cuam tshuam hauv qhov chaw nruab nrab ntawm La2O3 thiab CO2 tsim La2O2CO3mesophase, uas ua rau muaj kev tshem tawm zoo ntawm CxHy ntawm cov catalyst nto. La2O3 txhawb nqa kev txo qis hydrogen los ntawm kev muab cov hluav taws xob ntau dua thiab ua kom cov pa oxygen tsis txaus hauv 10% Co / MA. Qhov sib ntxiv ntawm La2O3 txo qhov pom kev ua kom lub zog ntawm CH4consumption. Yog li ntawd, qhov kev hloov pauv ntawm CH4 nce mus rau 93.7% ntawm 1073K K. Qhov sib ntxiv ntawm La2O3 txhim kho cov kev ua haujlwm catalytic, txhawb kev txo qis H2, nce tus naj npawb ntawm Co0 active chaw, tsim cov pa roj carbon tsawg dua thiab nce cov pa tawm mus rau 73.3%.

Ce thiab Pr tau txais kev txhawb nqa ntawm Ni / Al2O3catalyst los ntawm kev sib npaug ntim impregnation hauv Li Xiaofeng. Tom qab ntxiv Ce thiab Pr, qhov kev xaiv rau H2 nce ntxiv thiab kev xaiv rau CO txo qis. MDR hloov kho los ntawm Pr muaj peev xwm catalytic zoo heev, thiab kev xaiv rau H2 nce los ntawm 64.5% mus rau 75.6%, thaum qhov kev xaiv rau CO poob ntawm 31.4% Peng Shujing li al. siv sol-gel txoj kev, Ce-hloov MA tau npaj nrog txhuas isopropoxide, isopropanol hnyav thiab cerium nitrate hexahydrate. Qhov tshwj xeeb thaj chaw ntawm cov khoom tau nce me ntsis. Qhov sib ntxiv ntawm Ce txo qhov sib sau ua ke ntawm pas nrig zoo li nanoparticles ntawm MA nto. Qee pawg hydroxyl nyob rau saum npoo ntawm γ- Al2O3 tau pib them los ntawm Ce compounds. Lub thermal stability ntawm MA tau txhim kho, thiab tsis muaj crystal theem transformation tshwm sim tom qab calcination ntawm 1000 ℃ rau 10 teev.Wang Baowei li al. npaj MA cov ntaub ntawv CeO2-Al2O4 los ntawm txoj kev coprecipitation. CeO2 nrog cubic me me nplej tau sib xyaw ua ke hauv alumina. Tom qab kev txhawb nqa Co thiab Mo ntawm CeO2-Al2O4, kev sib cuam tshuam ntawm alumina thiab cov khoom nquag Co thiab Mo tau cuam tshuam zoo los ntawm CEO2.

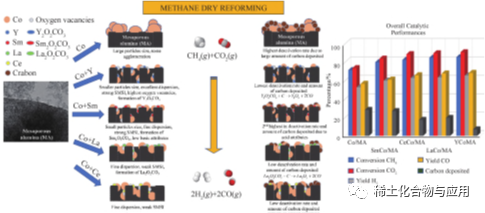

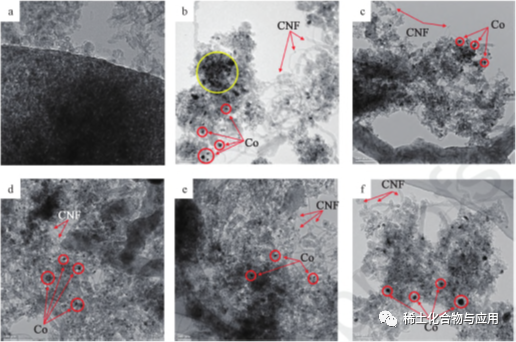

Cov neeg txhawb nqa lub ntiaj teb tsis tshua muaj (La, Ce, y thiab Sm) tau ua ke nrog Co/MA catalyst rau MDR, thiab cov txheej txheem tau qhia hauv daim duab. 3. Cov neeg txhawb nqa lub ntiaj teb tsis tshua muaj peev xwm txhim kho cov dispersion ntawm Co ntawm MA cab kuj thiab inhibit cov agglomeration ntawm co hais. qhov me me me me, qhov muaj zog ntawm Co-MA kev sib cuam tshuam, lub zog catalytic thiab sintering muaj peev xwm hauv YCo / MA catalyst, thiab cov txiaj ntsig zoo ntawm ntau tus neeg txhawb nqa ntawm MDR kev ua thiab carbon deposition.Fig. 4 yog HRTEM iMAge tom qab kev kho MDR ntawm 1023K, Co2: ch4: N2 = 1 ∶ 1 ∶ 3.1 rau 8 teev. Co particles muaj nyob rau hauv daim ntawv ntawm cov pob dub, thaum MA cov cab kuj muaj nyob rau hauv daim ntawv ntawm grey, uas nyob ntawm qhov sib txawv ntawm electron ceev. nyob rau hauv HRTEM duab nrog 10% Co/MA (daim duab. 4b), lub agglomeration ntawm Co hlau hais yog pom nyob rau hauv macarriersQhov sib ntxiv ntawm tsawg lub ntiaj teb promoter txo Co hais mus rau 11.0nm ~ 12.5nm. YCo / MA muaj zog Co-MA kev sib cuam tshuam, thiab nws cov kev ua haujlwm sintering zoo dua li lwm cov catalysts. Tsis tas li ntawd, raws li qhia nyob rau hauv figs. 4b mus rau 4f, hollow carbon nanowires (CNF) yog tsim nyob rau hauv cov catalysts, uas nyob rau hauv kev sib cuag nrog roj ntws thiab tiv thaiv lub catalyst los ntawm deactivation.

Fig. 3 Cov nyhuv ntawm lub ntiaj teb tsis tshua muaj ntxiv rau lub cev thiab tshuaj lom neeg thiab MDR catalytic kev ua tau zoo ntawm Co/MA catalyst

3.2.2 Deoxidation catalyst

Fe2O3 / Meso-CeAl, Ce-doped Fe-raws li deoxidation catalyst, tau npaj los ntawm oxidative dehydrogenation ntawm 1-butene nrog CO2as mos oxidant, thiab tau siv nyob rau hauv lub synthesis ntawm 1,3- butadiene (BD). Ce tau tawg heev nyob rau hauv alumina matrix, thiab Fe2O3 / meso yog heev dispersedFe2O3 / Meso-CeAl-100 catalyst tsis tsuas yog muaj heev dispersed hlau hom thiab zoo structural zog, tab sis kuj muaj zoo oxygen cia muaj peev xwm, yog li nws muaj zoo adsorption thiab ua kom muaj peev xwm ntawm CO2. Raws li pom nyob rau hauv daim duab 5, TEM cov duab qhia tau hais tias Fe2O3 / Meso-CeAl-100 yog tsis tu ncua Nws qhia tau hais tias cov cab zoo li channel qauv ntawm MesoCeAl-100 yog xoob thiab ntxeem tau, uas yog zoo rau dispersion ntawm active cov khoom xyaw, thaum heev dispersed Ce yog ntse doped nyob rau hauv alumina matrix. Noble hlau catalyst txheej cov khoom ua tau raws li tus qauv ultra-low emission ntawm lub cev muaj zog tsheb tau tsim pore qauv, zoo hydrothermal stability thiab loj oxygen cia muaj peev xwm.

3.2.3 Catalyst rau Tsheb

Pd-Rh txhawb nqa quaternary aluminium-raws li tsis tshua muaj ntiaj teb complexes AlCeZrTiOx thiab AlLaZrTiOx kom tau txais cov khoom siv hluav taws xob catalyst txheej. mesoporous aluminium-raws li tsis tshua muaj ntiaj teb complex Pd-Rh / ALC tuaj yeem siv tau zoo li CNG lub tsheb tso pa purification catalyst nrog kev ua haujlwm zoo, thiab kev hloov pauv ntawm CH4, lub ntsiab lus tseem ceeb ntawm CNG tsheb tso pa roj, yog siab li 97.8%. Txais yuav ib txoj kev hydrotherMAl ib kauj ruam los npaj cov khoom siv tsis tshua muaj hauv ntiaj teb ma cov khoom sib xyaw kom paub txog kev sib dhos ntawm tus kheej, Ordered mesoporous precursors nrog metastable xeev thiab siab aggregation tau ua ke, thiab cov synthesis ntawm RE-Al conformed rau tus qauv ntawm "compound growth unit", yog li realizing lub purification ntawm lub tsheb-tshaj peb catway.

Fig. 4 HRTEM images of ma (a), Co/ MA(b), LaCo/MA(c), CeCo/MA(d), YCo/MA(e) and SmCo/MA(f)

Fig. 5 TEM image (A) and EDS element diagram (b,c) of Fe2O3/Meso-CeAl-100

3.3 luminous kev ua tau zoo

Cov hluav taws xob ntawm lub ntiaj teb tsis tshua muaj cov ntsiab lus tau yooj yim zoo siab rau kev hloov pauv ntawm qib sib txawv ntawm lub zog thiab tawm lub teeb. Lub ntiaj teb tsis tshua muaj ions feem ntau yog siv los ua cov activators los npaj cov khoom siv luminescent. Tsis tshua muaj lub ntiaj teb ions tuaj yeem thauj khoom rau ntawm qhov chaw ntawm aluminium phosphate hollow microspheres los ntawm txoj kev coprecipitation thiab ion pauv txoj kev, thiab cov ntaub ntawv luminescent AlPO4∶RE (La, Ce, Pr, Nd) tuaj yeem npaj. Lub luminescent wavelength yog nyob ze ntawm cheeb tsam ultraviolet.MA yog ua rau nyias zaj duab xis vim nws inertia, tsis tshua muaj dielectric tas li thiab tsis tshua muaj conductivity, uas ua rau nws muaj feem xyuam rau hluav taws xob thiab kho qhov muag li, nyias zaj duab xis, teeb meem, sensors, thiab lwm yam. Nws kuj yuav siv tau rau sensing teb ib-dimensional photonic crystals, zog tiam thiab anti-reflection. Cov khoom siv no yog cov yeeb yaj kiab uas muaj qhov ntev ntawm qhov kho qhov muag, yog li nws yog ib qho tsim nyog los tswj cov refractive index thiab thickness.Tam sim no, titanium dioxide thiab zirconium oxide nrog siab refractive index thiab silicon dioxide nrog tsawg refractive index feem ntau yog siv los tsim thiab tsim cov khoom siv zoo li no. Qhov muaj ntau yam ntawm cov ntaub ntawv nrog cov khoom sib txawv ntawm cov tshuaj lom neeg tau nthuav dav, uas ua rau nws muaj peev xwm tsim cov photon sensors siab heev. Kev taw qhia ntawm MA thiab oxyhydroxide films hauv kev tsim cov khoom siv kho qhov muag pom tau tias muaj peev xwm zoo vim tias qhov ntsuas qhov cuam tshuam zoo ib yam li cov silicon dioxide.Tab sis cov tshuaj lom neeg sib txawv.

3.4 thermal stability

Nrog rau qhov nce ntawm qhov kub thiab txias, sintering cuam tshuam rau kev siv cov nyhuv ntawm MA catalyst, thiab cov cheeb tsam tshwj xeeb txo qis thiab γ-Al2O3in crystalline theem hloov mus rau δ thiab θ mus rau χ theem. Cov ntaub ntawv tsis tshua muaj hauv ntiaj teb muaj kev ruaj ntseg zoo thiab thermal stability, siab adaptability, thiab yooj yim muaj thiab pheej yig raw cov ntaub ntawv. Qhov sib ntxiv ntawm cov ntsiab lus tsis tshua muaj hauv ntiaj teb tuaj yeem txhim kho cov thermal stability, kub oxidation tsis kam thiab cov khoom siv kho tshuab ntawm cov cab kuj, thiab kho cov acidity ntawm cov cab kuj.La thiab Ce yog cov feem ntau siv thiab kawm kev hloov kho cov ntsiab lus. Lu Weiguang thiab lwm tus tau pom tias qhov sib ntxiv ntawm cov ntsiab lus tsis tshua muaj hauv ntiaj teb tiv thaiv qhov sib txawv ntawm cov alumina hais, La thiab Ce tiv thaiv cov pawg hydroxyl nyob rau saum npoo ntawm alumina, inhibited sintering thiab theem transformation, thiab txo qhov kev puas tsuaj ntawm kub kub rau mesoporous qauv. Cov alumina npaj tseem muaj qhov tshwj xeeb ntawm qhov chaw thiab qhov pore ntim.Txawm li cas los xij, ntau dhau los yog tsawg dhau lub ntiaj teb cov ntsiab lus yuav txo cov thermal stability ntawm alumina. Li Yanqiu et al. ntxiv 5% La2O3to γ-Al2O3, uas txhim kho cov thermal stability thiab nce lub pore ntim thiab thaj tsam ntawm alumina carrier. Raws li pom tau los ntawm daim duab 6, La2O3 ntxiv rau γ-Al2O3, Txhim kho cov thermal stability ntawm lub ntiaj teb tsis tshua muaj cov cab kuj.

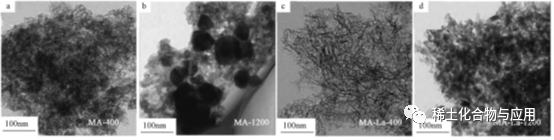

Nyob rau hauv tus txheej txheem ntawm doping nano-fibrous hais nrog La rau MA, BET nto cheeb tsam thiab pore ntim ntawm MA-La yog siab dua li cov MA thaum lub tshav kub kho kub nce, thiab doping nrog La muaj pom tseeb retarding nyhuv ntawm sintering ntawm kub. raws li qhia hauv daim duab. 7, nrog rau qhov kub thiab txias, La inhibits cov tshuaj tiv thaiv ntawm grain loj hlob thiab theem transformation, thaum figs. 7a thiab 7c qhia txog kev sib sau ntawm nano-fibrous hais. hauv fig. 7b, txoj kab uas hla ntawm cov khoom loj uas ua los ntawm calcination ntawm 1200 ℃ yog hais txog 100nm.Nws cim qhov tseem ceeb sintering ntawm MA. Tsis tas li ntawd, piv nrog MA-1200, MA-La-1200 tsis sib sau ua ke tom qab kev kho cua sov. Nrog rau qhov sib ntxiv ntawm La, nano-fiber hais muaj peev xwm sintering zoo dua. txawm nyob rau ntawm qhov kub ntawm calcination ntau dua, doped La tseem tawg heev ntawm MA nto. La modified MA tuaj yeem siv los ua tus nqa khoom ntawm Pd catalyst hauv C3H8oxidation cov tshuaj tiv thaiv.

Fig. 6 Cov qauv qauv ntawm sintering alumina nrog thiab tsis tshua muaj ntiaj teb cov ntsiab lus

Fig. 7 TEM images of MA-400(a), MA-1200(b), MA-La-400(c) and MA-La-1200(d)

4 Kev xaus

Kev nce qib ntawm kev npaj thiab kev ua haujlwm ntawm cov ntaub ntawv tsis tshua muaj hauv ntiaj teb hloov kho MA tau qhia. Tsis tshua muaj ntiaj teb hloov MA yog dav siv. Txawm hais tias ntau qhov kev tshawb fawb tau ua tiav hauv daim ntawv thov catalytic, thermal stability thiab adsorption, ntau cov ntaub ntawv muaj tus nqi siab, tsis tshua muaj nqi doping, kev txiav txim tsis zoo thiab nyuaj rau kev lag luam. Cov hauj lwm hauv qab no yuav tsum tau ua rau yav tom ntej: ua kom zoo tshaj qhov muaj pes tsawg leeg thiab cov qauv ntawm lub ntiaj teb tsis tshua muaj kev hloov kho MA, xaiv cov txheej txheem tsim nyog, Ua tau raws li kev ua haujlwm zoo; Tsim cov txheej txheem tswj cov qauv raws li cov txheej txheem ua haujlwm kom txo tau cov nqi thiab paub txog kev tsim khoom lag luam; Txhawm rau kom ua tiav qhov txiaj ntsig zoo ntawm Tuam Tshoj cov peev txheej tsawg hauv ntiaj teb, peb yuav tsum tshawb xyuas cov txheej txheem ntawm lub ntiaj teb tsis tshua muaj MA hloov kho, txhim kho txoj kev xav thiab txheej txheem ntawm kev npaj lub ntiaj teb tsis tshua muaj hloov MA.

Txoj Haujlwm Pab Nyiaj: Shaanxi Science thiab Technology Overall Innovation Project (2011KTDZ01-04-01); Shaanxi Xeev 2019 Kev Tshawb Fawb Txog Kev Tshawb Fawb Tshwj Xeeb (19JK0490); 2020 tshwj xeeb kev tshawb fawb txog kev tshawb fawb ntawm Huaqing College, Xi 'an University of Architecture thiab Technology (20KY02)

Tau qhov twg los: Rare Earth

Lub sij hawm xa tuaj: Plaub Hlis-04-2022