Tantalum pentachloride (TaCl₅) - feem ntau hu ua yooj yimtantalum chloride tshuaj- yog ib qho dawb, dej-soluble crystalline hmoov uas ua hauj lwm raws li ntau yam precursor nyob rau hauv ntau cov txheej txheem high-tech. Hauv metallurgy thiab chemistry, nws muab qhov zoo tshaj plaws ntawm cov ntshiab tantalum: cov neeg muag khoom nco ntsoov tias "Tantalum (V) chloride yog qhov zoo tshaj plaws dej soluble crystalline tantalum qhov chaw". Cov reagent no pom cov ntawv thov tseem ceeb nyob qhov twg ultrapure tantalum yuav tsum tau tso lossis hloov pauv: los ntawm microelectronic atomic layer deposition (ALD) mus rau corrosion-tiv thaiv txheej hauv aerospace. Hauv tag nrho cov ntsiab lus no, cov khoom siv purity yog qhov tseem ceeb - qhov tseeb, cov ntawv thov kev ua haujlwm siab feem ntau xav tau TaCl₅ ntawm "> 99.99% purity". Cov nplooj ntawv EpoMaterial (CAS 7721-01-9) qhia meej meej xws li high-purity TaCl₅ (99.99%) raws li cov khoom pib rau qib siab tantalum chemistry. Nyob rau hauv luv luv, TaCl₅ yog ib tug linchpin nyob rau hauv lub fabrication ntawm cutting-edge pab kiag li lawm - los ntawm 5nm semiconductor nodes mus rau lub zog-storage capacitors thiab corrosion-resistant qhov chaw - vim hais tias nws muaj peev xwm ntseeg tau xa atomically ntshiab tantalum nyob rau hauv kev tswj tej yam kev mob.

Daim duab: High-purity tantalum chloride (TaCl₅) feem ntau yog cov hmoov dawb crystalline siv los ua qhov chaw ntawm tantalum hauv tshuaj vapor deposition thiab lwm yam txheej txheem.

Chemical Properties thiab Purity

Chemically, tantalum pentachloride yog TaCl₅, nrog ib tug molecular luj ntawm 358.21 thiab ib tug melting point nyob ib ncig ntawm 216 ° C. Nws yog rhiab heev rau ya raws thiab undergoes hydrolysis, tab sis nyob rau hauv inert tej yam kev mob nws sublimes thiab decomposes huv si. TaCl₅ tuaj yeem ua sublimed lossis distilled kom ua tiav ultra-siab purity (feem ntau 99.99% lossis ntau dua). Rau semiconductor thiab aerospace siv, xws li purity yog tsis-negotiable: kab impurities nyob rau hauv lub precursor yuav xaus li tsis xws luag nyob rau hauv nyias films los yog alloy deposits. High-purity TaCl₅ xyuas kom meej tias cov tantalum tso los yog tantalum tebchaw muaj qhov paug tsawg. Tseeb, manufacturers ntawm semiconductor precursors qhia meej txog cov txheej txheem (zone refining, distillation) kom ua tiav "> 99.99% purity" hauv TaCl₅, ua tau raws li "semiconductor-qib cov qauv" rau qhov tsis xws luag-dawb deposition.

Lub EpoMaterial teev nws tus kheej underscores qhov kev thov no: nwsTaCl ₅cov khoom tau teev tseg ntawm 99.99% purity, qhia raws nraim cov qib uas xav tau rau cov txheej txheem nyias nyias. Kev ntim khoom thiab cov ntaub ntawv feem ntau suav nrog Daim Ntawv Pov Thawj Kev Tshawb Fawb uas lees paub cov ntsiab lus hlau thiab cov khoom seem. Piv txwv li, ib txoj kev tshawb fawb CVD siv TaCl₅ "nrog kev huv huv ntawm 99.99%" raws li muab los ntawm tus neeg muag khoom tshwj xeeb, ua kom pom tias cov chaw soj nstuam saum toj kawg nkaus los ntawm cov khoom siv qib siab. Nyob rau hauv kev xyaum, sub-10 ppm theem ntawm hlau impurities (Fe, Cu, thiab lwm yam) yuav tsum tau; Txawm tias 0.001-0.01% ntawm impurity tuaj yeem rhuav tshem lub rooj vag dielectric lossis lub tshuab hluav taws xob siab. Yog li, purity tsis yog kev lag luam xwb - nws yog ib qho tseem ceeb kom ua tiav qhov kev ua tau zoo thiab kev ntseeg siab xav tau los ntawm cov khoom siv hluav taws xob niaj hnub no, cov tshuab hluav taws xob ntsuab, thiab cov khoom siv dav hlau.

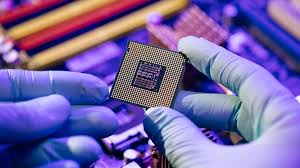

Lub luag haujlwm hauv Semiconductor Fabrication

Hauv kev tsim khoom semiconductor, TaCl₅ feem ntau yog siv los ua cov tshuaj vapor deposition (CVD) precursor. Hydrogen txo ntawm TaCl₅ yields elemental tantalum, ua rau tsim cov hlau ultrathin lossis dielectric films. Piv txwv li, cov txheej txheem plasma-pab CVD (PACVD) tau pom tias

tuaj yeem tso siab purity tantalum hlau ntawm substrates ntawm qhov kub nruab nrab. Cov tshuaj tiv thaiv no yog huv si (tsuas yog tsim HCl raws li cov khoom lag luam) thiab ua rau cov yeeb yaj kiab Ta zoo sib xws txawm tias nyob hauv qhov tob tob. Tantalum hlau khaubncaws sab nraud povtseg yog siv raws li diffusion barriers los yog adhesion khaubncaws sab nraud povtseg nyob rau hauv interconnect stacks: ib tug Ta los yog TaN barrier tiv thaiv tooj liab tsiv mus nyob rau hauv silicon, thiab TaCl₅-raws li CVD yog ib txoj hauv kev rau tso cov khaubncaws sab nraud povtseg ntawm complex topologies.

Tshaj li cov hlau ntshiab, TaCl₅ tseem yog ALD precursor rau tantalum oxide (Ta₂O₅) thiab tantalum silicate films. Atomic Layer Deposition (ALD) cov tswv yim siv TaCl₅ pulses (feem ntau nrog O₃ lossis H₂O) kom loj hlob Ta₂O₅ ua lub siab-κ dielectric. Piv txwv li, Jeong et al. ua qauv qhia ALD ntawm Ta₂O₅ los ntawm TaCl₅ thiab ozone, ua tiav ~ 0.77 Å ib lub voj voog ntawm 300 ° C. Xws li Ta₂O₅ cov khaubncaws sab nraud povtseg yog cov muaj peev xwm sib tw rau tiam tom ntej lub rooj vag dielectrics lossis nco (ReRAM) cov khoom siv, ua tsaug rau lawv cov dielectric siab thiab ruaj khov. Nyob rau hauv cov logic thiab nco chips, cov khoom siv engineers nce tso siab rau TaCl₅-raws li deposition rau "sub-3nm node" technology: ib tug tshwj xeeb tsum sau ntawv tias TaCl₅ yog ib tug "zoo tshaj plaws precursor rau CVD / ALD txheej txheem rau tso tantalum-raws li barrier txheej thiab rooj vag oxides nyob rau hauv 5nm / 3nm architecture chips". Hauv lwm lo lus, TaCl₅ zaum ntawm lub plawv ntawm kev ua kom qhov tseeb Moore Txoj Cai scaling.

Txawm tias nyob rau hauv cov kauj ruam photoresist thiab qauv, TaCl₅ pom kev siv: chemists siv nws ua ib tug chlorinating tus neeg sawv cev nyob rau hauv etch los yog lithography txheej txheem los qhia tantalum residues rau xaiv daim npog qhov ncauj. Thiab thaum lub sij hawm ntim, TaCl₅ tuaj yeem tsim kev tiv thaiv Ta₂O₅ txheej ntawm sensors lossis MEMS li. Nyob rau hauv tag nrho cov ntsiab lus ntawm semiconductor, tus yuam sij yog tias TaCl₅ tuaj yeem raug xa mus rau hauv daim ntawv vapor, thiab nws cov kev hloov pauv ua cov yeeb yaj kiab ntom ntom. Qhov no underlines vim li cas semiconductor fabs qhia tsuas yog covsiab tshaj-purity TaCl₅- vim tias txawm tias cov kab mob ppb-theem yuav tshwm sim raws li qhov tsis xws luag hauv chip gate dielectrics lossis interconnects.

Enabling Sustainable Energy Technologies

Tantalum compounds ua lub luag haujlwm tseem ceeb hauv cov khoom siv ntsuab-zog thiab lub zog khaws cia, thiab tantalum chloride yog ib qho kev txhawb nqa ntawm cov khoom siv. Piv txwv li, tantalum oxide (Ta₂O₅) yog siv los ua dielectric nyob rau hauv high-performance capacitors - tshwj xeeb tshaj yog tantalum electrolytic capacitors thiab tantalum-based supercapacitors - uas yog ib qho tseem ceeb nyob rau hauv renewable-zog tshuab thiab hluav taws xob electronics. Ta₂O₅ muaj cov txheeb ze permittivity siab (ε_r ≈ 27), ua kom cov capacitors siab capacitance ib ntim. Kev lag luam cov ntaub ntawv sau tseg tias "Ta₂O₅ dielectric ua rau muaj kev ua haujlwm ntau dua AC ... Hauv kev xyaum, TaCl₅ tuaj yeem hloov pauv mus rau Ta₂O₅ faib ua cov hmoov nplej los yog nyias zaj duab xis rau cov capacitors. Piv txwv li, electrolytic capacitor's anode feem ntau yog sintered ntxeem tau tantalum nrog Ta₂O₅ dielectric zus los ntawm electrochemical oxidation; tantalum hlau nws tus kheej tuaj yeem los ntawm TaCl₅-derived deposition tom qab oxidation.

Tshaj li cov capacitors, tantalum oxides thiab nitrides tau tshawb nrhiav hauv cov roj teeb thiab roj cell. Kev tshawb fawb tsis ntev los no taw qhia rau Ta₂O₅ ua cov khoom cog lus Li-ion roj teeb anode vim nws lub peev xwm siab thiab ruaj khov. Tantalum-doped catalysts tuaj yeem txhim kho dej-splitting rau hydrogen tiam. Txawm hais tias TaCl₅ nws tus kheej tsis ntxiv rau cov roj teeb, nws yog txoj hauv kev los npaj nano-tantalum thiab Ta-oxide ntawm pyrolysis. Piv txwv li, cov neeg muag khoom ntawm TaCl₅ cov npe "supercapacitor" thiab "high CV (coefficient of variation) tantalum hmoov" nyob rau hauv lawv daim ntawv teev npe, hinting ntawm kev siv zog-kho siab heev. Ib daim ntawv dawb txawm hais txog TaCl₅ hauv txheej txheej rau chlor-alkali thiab oxygen electrodes, qhov twg Ta-oxide overlayer (sib xyaw nrog Ru / Pt) txuas lub neej electrode los ntawm kev tsim cov yeeb yaj kiab zoo.

Nyob rau hauv loj-scale renewables, tantalum Cheebtsam ua rau kom lub cev resilience. Piv txwv li, Ta-based capacitors thiab cov ntxaij lim dej stabilize voltage hauv cua turbines thiab hnub ci inverters. Advanced cua-turbine fais fab hluav taws xob siv hluav taws xob tuaj yeem siv Ta-muaj cov txheej txheem dielectric uas tsim los ntawm TaCl₅ precursors. Ib qho piv txwv ntawm cov toj roob hauv pes tsim dua tshiab:

Daim duab: Cua turbines ntawm qhov chaw siv hluav taws xob tauj dua tshiab. Lub tshuab hluav taws xob muaj hluav taws xob siab hauv cua thiab hnub ci ua liaj ua teb feem ntau tso siab rau cov khoom siv hluav taws xob thiab cov dielectrics siab heev (xws li Ta₂O₅) kom lub zog du thiab txhim kho kev ua haujlwm. Tantalum precursors zoo li TaCl₅ txhawb kev tsim ntawm cov khoom no.

Tsis tas li ntawd, tantalum's corrosion resistance (tshwj xeeb tshaj yog nws Ta₂O₅ nto) ua rau nws txaus nyiam rau roj hlwb thiab electrolyzers hauv kev lag luam hydrogen. Cov catalysts tshiab siv TaOx kev txhawb nqa kom ruaj khov cov hlau muaj txiaj ntsig lossis ua raws li cov catalysts lawv tus kheej. Piv txwv li, cov thev naus laus zis niaj hnub siv hluav taws xob - los ntawm cov phiajcim ntse mus rau EV chargers - feem ntau nyob ntawm cov khoom siv tau los ntawm tantalum, thiab TaCl₅ yog cov khoom noj tseem ceeb rau kev ua rau lawv muaj siab huv.

Aerospace thiab High-Precision Applications

Hauv aerospace, tantalum tus nqi yog nyob rau hauv kev ruaj ntseg heev. Nws tsim ib qho impervious oxide (Ta₂O₅) uas tiv thaiv corrosion thiab kub-kub yaig. Cov khoom uas pom kev nruj heev - turbines, foob pob ua ntxaij, los yog cov khoom siv tshuaj - siv tantalum coatings los yog alloys. Ultramet (lub tuam txhab cov ntaub ntawv ua tau zoo) siv TaCl₅ hauv cov txheej txheem tshuaj vapor kom diffuse Ta mus rau hauv superalloys, txhim kho lawv cov tshuaj tiv thaiv acid thiab hnav. Qhov tshwm sim: cov khoom (xws li li qub, cov khoom siv hluav taws xob sib hloov) uas tuaj yeem tiv taus cov foob pob hluav taws hnyav lossis cov dav hlau corrosive yam tsis muaj kev puas tsuaj.

High-purity TaCl₅kuj yog siv los tso cov iav zoo li Ta coatings thiab cov yeeb yaj kiab kho qhov muag rau qhov chaw optics lossis laser tshuab. Piv txwv li, Ta₂O₅ yog siv los tiv thaiv kev cuam tshuam ntawm cov iav aerospace thiab precision lo ntsiab muag, qhov twg txawm me me impurity theem yuav cuam tshuam qhov kev ua tau zoo. Ib daim ntawv qhia tus neeg muag khoom qhia tau hais tias TaCl₅ ua rau "tiv thaiv kev cuam tshuam thiab cov txheej txheem rau aerospace-qib iav thiab qhov tseeb lo ntsiab muag". Ib yam li ntawd, cov radar siab heev thiab cov tshuab sensor siv tantalum hauv lawv cov khoom siv hluav taws xob thiab cov txheej txheem, txhua yam pib los ntawm high-purity precursors.

Txawm nyob rau hauv additive manufacturing thiab metallurgy, TaCl₅ pab. Thaum cov tantalum hmoov ntau yog siv rau hauv 3D luam ntawv ntawm kev kho mob cog thiab aerospace qhov chaw, txhua yam tshuaj etching lossis CVD ntawm cov hmoov no feem ntau tso siab rau chloride chemistry. Thiab high-purity TaCl₅ nws tus kheej tuaj yeem ua ke nrog lwm cov precursors hauv cov txheej txheem tshiab (xws li organometallic chemistry) los tsim cov superalloys nyuaj.

Zuag qhia tag nrho, tus qauv yog qhov tseeb: qhov xav tau tshaj plaws aerospace thiab kev tiv thaiv thev naus laus zis hais rau "qib tub rog lossis kho qhov muag" tantalum compounds. EpoMaterial qhov kev muab ntawm "mil-spec"–qib TaCl₅ (nrog USP / EP ua raws) cuam tshuam rau cov haujlwm no. Raws li ib tug high-purity tsum hais tias, "peb cov khoom tantalum yog cov khoom tseem ceeb rau kev tsim khoom ntawm electronics, superalloys nyob rau hauv lub aerospace sector, thiab corrosion kuj txheej txheem." Lub ntiaj teb kev tsim khoom siab heev tsuas tuaj yeem ua haujlwm yam tsis muaj cov khoom noj khoom haus huv huv tantalum uas TaCl₅ muab.

Qhov tseem ceeb ntawm 99.99% Purity

Vim li cas 99.99%? Cov lus teb yooj yim: vim hais tias nyob rau hauv technology, impurities yog tuag taus. Ntawm nanoscale ntawm cov chips niaj hnub no, ib qho atom uas muaj kab mob tuaj yeem tsim txoj hauv kev los yog ntxiab nqi. Nyob rau hauv high voltages ntawm lub hwj chim electronics, ib tug impurity yuav pib dielectric puas. Nyob rau hauv corrosive aerospace ib puag ncig, txawm ppm-theem catalyst accelerants tuaj yeem tua hlau. Yog li, cov ntaub ntawv zoo li TaCl₅ yuav tsum yog "qib hluav taws xob."

Cov ntaub ntawv kev lag luam underscores qhov no. Hauv plasma CVD txoj kev tshawb fawb saum toj no, cov sau phau ntawv qhia meej meej xaiv TaCl₅ "vim nws qhov nruab nrab ntawm qhov pom zoo [vapor] qhov tseem ceeb" thiab nco ntsoov tias lawv siv "99.99% purity" TaCl₅. Lwm tus neeg muab kev sau ntawv khav theeb: "Peb TaCl₅ ua tiav> 99.99% purity los ntawm kev ua kom zoo tshaj plaws thiab thaj chaw ua kom zoo dua… ua tau raws li cov qauv semiconductor-qib. Hauv lwm lo lus, cov txheej txheem engineers nyob ntawm qhov plaub-nine purity.

High purity kuj cuam tshuam cov txheej txheem yields thiab kev ua tau zoo. Piv txwv li, nyob rau hauv ALD ntawm Ta₂O₅, tej chlorine residual los yog hlau impurities yuav hloov cov zaj duab xis stoichiometry thiab dielectric tas li. Hauv electrolytic capacitors, kab hlau nyob hauv txheej oxide tuaj yeem ua rau cov dej ntws tawm. Thiab nyob rau hauv Ta-alloys rau lub dav hlau xyaw, cov ntsiab lus ntxiv tuaj yeem tsim cov theem tsis zoo. Yog li ntawd, cov ntaub ntawv cov ntaub ntawv feem ntau qhia ob qho tib si tshuaj purity thiab qhov tso cai impurity (feem ntau <0.0001%). Daim ntawv EpoMaterial spec rau 99.99% TaCl₅ qhia impurity tag nrho hauv qab 0.0011% los ntawm qhov hnyav, qhia txog cov qauv nruj no.

Cov ntaub ntawv kev ua lag luam qhia txog tus nqi ntawm cov purity zoo li no. Cov kws tshuaj ntsuam tau tshaj tawm tias 99.99% tantalum hais kom muaj txiaj ntsig zoo. Piv txwv li, ib daim ntawv tshaj tawm kev lag luam sau tseg tantalum tus nqi tau tsav siab dua los ntawm qhov kev thov rau "99.99% purity" cov khoom. Tseeb, lub ntiaj teb no tantalum kev ua lag luam (hlau thiab cov khoom sib xyaw ua ke) yog kwv yees li $ 442 lab hauv 2024, nrog kev loj hlob mus txog $ 674 lab los ntawm 2033 - ntau qhov kev thov no yog los ntawm high-tech capacitors, semiconductors, thiab aerospace, tag nrho xav tau cov khoom ntshiab Ta.

Tantalum chloride (TaCl₅) yog ntau tshaj li cov tshuaj xav paub: nws yog lub pob zeb tseem ceeb ntawm kev tsim khoom siv high-tech niaj hnub no. Nws qhov tshwj xeeb ua ke ntawm volatility, reactivity, thiab muaj peev xwm los tawm pristine Ta los yog Ta-compounds ua rau nws indispensable rau semiconductors, sustainable zog, thiab aerospace cov ntaub ntawv. Los ntawm kev ua kom muaj kev tso tawm ntawm atomically nyias Ta zaj duab xis nyob rau hauv qhov tseeb 3nm chips, los txhawb cov dielectric txheej nyob rau hauv tiam tom ntej capacitors, tsim cov corrosion-proof coatings ntawm aircraft, high-purity TaCl₅ nyob ntsiag to nyob txhua qhov chaw.

Raws li kev thov rau lub zog ntsuab, cov khoom siv hluav taws xob me me, thiab cov tshuab ua haujlwm siab loj hlob tuaj, lub luag haujlwm ntawm TaCl₅ tsuas yog nce. Cov neeg muag khoom zoo li EpoMaterial lees paub qhov no los ntawm kev muab TaCl₅ hauv 99.99% purity rau raws nraim cov ntawv thov no. Hauv luv luv, tantalum chloride yog cov khoom siv tshwj xeeb ntawm lub plawv ntawm "txiav-ntev" thev naus laus zis. Nws cov chemistry tej zaum yuav qub (nrhiav hauv 1802), tab sis nws cov ntawv thov yog yav tom ntej.

Post lub sij hawm: May-26-2025